RoboSense, a smart LiDAR Sensor provider, announced a partnership with FAW (“First Automobile Works”), an automotive OEM (Original Equipment Manufacturer), and showcased the milestone achievement of last year’s cooperation: the first batch of world’s first solid-state Smart LiDAR Sensor RS-LiDAR-M1 on September 25. The deal is to include RS-LiDAR-M1 as core component into FAW’s proprietary next-generation autonomous driving system development, therefore accelerating the serial production of the world’s first automotive-grade solid-state MEMS-based Smart LiDAR Sensor, in order to promote Level 3 vehicle autonomy and above.

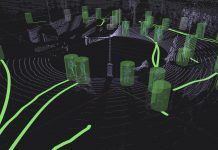

The final commercialized version of RS-LiDAR-M1 is the world’s first and only all-in-one unit MEMS-based Smart LiDAR Sensor for self-driving passenger vehicles with its own embedded AI algorithm technologies and SoC (System of Chip). It transforms traditional LiDAR systems (also known as solely data collectors), to full data analysis and comprehension systems. The RS-LiDAR-M1 not only collects and interprets high definition 3D point cloud data, but its built-in AI algorithm and SoC also process road data in real-time, while at the same time synchronizing outputs of high-precision localization, obstacle detection, tracking and classification, road curbs and driving areas detection.

Unlike RoboSense Smart LiDAR Sensor, when mechanical LiDAR is used on a vehicle, a computer-sized ECU must also be used to operate the algorithms. Compared with ECUs, the RoboSense dedicated SoC built into the Smart LiDAR Sensor not only withstands strong bumps and jolts in the vehicle, but is also small and light-weight. The RoboSense Smart LiDAR Sensor’s built-in SoC can largely reduce more power consumption while improving performance compared to automotive ECUs, saving much more passenger space at the same time.

The RS-LiDAR-M1 is cleanly designed in a streamlined body that allows it to be easily embedded onto any part of the vehicle for the complete aesthetics of automobile.

Serial produced RoboSense Smart LiDAR Sensor costs only hundreds of dollars each, based on its deployment of revolutionary MEMS micro-mirror scanning structure and simplified manufacturing and streamlines production, while maintaining high product quality and reliability to meet exacting OEM requirements.